What are the Differences Between Dry and Wet Type Ball Mill?

Ball mill Wikipedia

WhatsApp)

WhatsApp)

Ball mill Wikipedia

Charging a Wet Mill The general operation of a grinding mill is to have the product impacted between the balls as they tumble. Unlike dry milling, wet milling is more straight forward and more forgiving in terms of charging the product. As with dry milling there should be at least 25% liquid to fill the void space plus a bit more to insure the balls are striking product and not each other.

The wet ball mill has two types as follow: grid type and overflow grain size limit of the grinding mill is usually ~, so it is commonly used in the first segment. The particle size of the grinding mill is generally less than, so it is suitable for the second grinding of the middle product in the twostage grinding

HelloIn our iron concentrator plant we use a wet ball mill for grinding of fresh feed. It operates in a close circle with hydrocyclones.

Wet Grid ball mill is mainly used for mixing and grinding materials in two types: dry grinding and wet grinding .It has advantages of fineness uniformity and power saving. The machine uses different types

Hello In our iron concentrator plant we use a wet ball mill for grinding of fresh feed. It operates in a close circle with hydrocyclones. The overall data of ball mill and hydrocyclones are following: Ball mill: F80: 4 mm Diameter: m Length: m Makeup regime of ball charge: sizes 4

Introduction. ELE Wet grinding Mill is mature technology, reliable and advanced processing. Include three types horizontal bead mill, Turbo type, Pin type, Disc type, suitable for different application and

Wet Grinding, also known as wet milling, is a process of taking materials in a liquid form or slurry and reducing particles, such as agglomerates, by breaking them apart or shearing them down in size.

Limestone Ball mill can devide into 2 types, wet ball mill and dry ball mill. Ball mill is a mineral processing machine for milling the materials into powders after they are crushed. It is widely applied to the

Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction. These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery. Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding to analytical fineness. They are used for the most demanding tasks in the laboratory, from routine sample processing to colloidal grinding

Mixer Mills grind and homogenize small sample volumes quickly and efficiently by impact and friction. These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA recovery. Planetary Ball Mills meet and exceed all requirements for fast and reproducible grinding

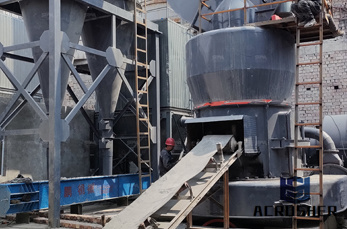

19 #0183;#32;GRINDING MILLS, GRINDERS. DOVE Ball Mills are size reduction machines, designed for

has designed, manufactured and installed over 8,000 ball and pebble mills all over the world for a wide range of applications. Some of those applications are grate discharge, peripheral discharge, dry grinding, special length to diameter ratio, high temperature milling

Introduction. ELE Wet grinding Mill is mature technology, reliable and advanced processing. Include three types horizontal bead mill, Turbo type, Pin type, Disc type, suitable for different application and different viscosity. Solve the problem of fineness, temperature, metal contaminationsetc. Wet grinding Mill

DOVE Ball Mills are size reduction machines, designed for grinding applications, where fine material is required. Applicable for wet and dry grinding applications within the following branches of industries:

Dec 01, 2013#0183;#32;Wet ball mill is one of the most predominantly used method for the purpose of mixing and grinding of raw materials in laboratories and industry,, . The ball mill process is very complicated

Aug 21, 2020#0183;#32;Wet grinding is generally used in mineral processing, because the wet ball mill has the advantages of strong materials adaptability, continuous production, large grinding ratio, easy to adjust the fineness of the milled products, and it is widely used at present.

WhatsApp)

WhatsApp)