How to build a Gas Furnace Melting Gold and Silver

#0183;#32; This short video demonstration shows how i built a small gas fired crucible melting furnace with some basic tools and ..

WhatsApp)

WhatsApp)

#0183;#32; This short video demonstration shows how i built a small gas fired crucible melting furnace with some basic tools and ..

Gold is an almost nonreactive metal, but halogens chlorine, bromine, fluorine and iodine can dissolve it. Chlorine is the cheapest and lightest product that can achieve this. Bleach is the chemical compound sodium hypochlorite. When combined with hydrochloric acid, the

If the metals have not dissolved completely during this time, raise the temperature of the furnace to about 1400 degrees C (or about 2552 degrees F). Step 4 Observe the Gold Separating. Continue to heat the slag until you can observe the molten gold begin to dissolve away from the rest of the slag.

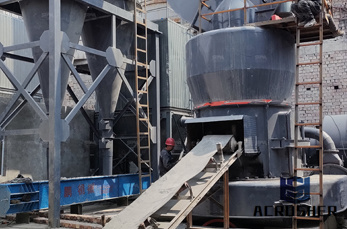

Electric Furnace Coal furnace; The gas torch is also used for gold melting. But gold dust can waste using a gas torch. The gas furnace is a good and affordable option for gold melting. An electric furnace is very useful and makes gold melting very easy. But, it is so expensive and everybody can not buy this. Coal furnace is the cheapest option.

#173;Smelting, which results in nearly pure gold, involves melting the negative terminals in a furnace at about 2,100 degrees F (1,149 degrees C). When workers add a chemical mixture known as flux to the molten material, the gold separates from the metal used to make

In the morning, however, take out the gold and melt it again, hammer it, and put it into the furnace as before. After another day and night take it out again, mix a little red copper with it, melt as before, and put it back into the furnace. And when you have taken it out a third time, wash it and carefully dry it.

The ore containing gold once mined from the earth is processed by separating gold minerals from the crude matter holding the ore together. The gold ore is then pulverized using pressure to create very fine particles. These fine particles are then heated in a furnace to temperatures above 1064 degrees Celsius the melting point of gold.

Stock Photo Separating lead from silver or gold in a cupellation furnace From Agricola Georg ''De re metallica'', Basel 1556 The Foreman consumed quantities of butter to avoid being poisoned to prevent absorption of lead in the stomach

Set the gold ore and a small quantity of lead in a cupel Place the cupel in a blast furnace Heat the mixture until the lead and gold ore liquefy The blast furnace batters the cupel with hot air The lead combines with other metals and forms oxide compounds that separate from the gold This process works best with small quantities of gold ore...We are a professional mining machinery manufacturer

Seperating Gold Useing A Furnace. Nov 26, 2009 Re: melting or seperating gold from fused silica Post by Harold_V November 26th, 2009, 6:25 am Chumbawamba wrote: After everything was put together and after a brief moment of admiration, I was banging the larger steel disk we used for the platform with a hammer to even it out and the iron disk that we''d welded to the steel tube broke off at

Load the solid gold ore into your crucible then load the furnace with charcoal. Light the charcoal and let it ash over. Set the crucible directly on the charcoal. Load more charcoal around the crucible. Turn the hair dryer on low to force air into the chamber below the charcoal.

#0183;#32;When mining copper ore, containing gold, what is the simplest approach to separating them to solid components. Gold Copper

#0183;#32;Gold machine that separate gold and gems from gravel. The machine is very unique in many ways. One thing is the fast clean up process that just take seconds

Use an electric furnace: Electric furnaces especially made for melting gold are now available in the market. They are usually small kilns that are high powered and meant to melt hard metals. Some electric furnaces are affordable and you can even purchase them

WhatsApp)

WhatsApp)