Hammer mill design calculation YouTube

#0183;#32;design calculation volume size power on hammer mills. power calculation for ball mills. ball mill power calculation pdf in India mills 229 In order to design hammer mill sizing calculation pdf

WhatsApp)

WhatsApp)

#0183;#32;design calculation volume size power on hammer mills. power calculation for ball mills. ball mill power calculation pdf in India mills 229 In order to design hammer mill sizing calculation pdf

A hammer mill is a mill whose purpose is to shred or crush aggregate material into smaller pieces by the repeated blows of little machines have numerous industrial applications, including: Ethanol plants (grains); A farm machine, which mills grain into coarse flour to be fed to livestock; Fluff pulp defiberizing; Fruit juice production; Grinding used shipping pallets for mulch

#0183;#32;Hammer Mill Design jasenterprise hammer mills htmlTechno wings hammer mill offers three series of hammer mills ideally suited for processing a wide variety of spices and dried herbs Each series will produce the exact desired finished size while preserving aroma and volatile oil qualities Hammer Mill Design fitzmill products view

Hammer Mill Design Calculation Hammer Mill Crusher Grinder Hammer Mill Working Principle The hammermill fundamentally is a simple mechanism The orthodox machine comprises a boxlike frame or housing a centrally disposed horizontalshaft rotating element rotor on which the hammers are mounted and usually a set of circumferentially arranged

Abstract. Hammer mill manufacturers are under increasing pressure to deliver mills of high productivity with a reduced level of vibrations. However, in practice, excessive wear of the rods carrying the hammers takes place, and cracks develop in the vicinity of the holes holding the rods with the hammers, with the possibility of breakaway fracture and disastrous consequences.

operating the hammer mill used to produce pelleting feed were drum speed of 2250 rpm ( m/s), grain moisture content (10%), concave clearance (5 mm) and hammer thickness (5 mm).

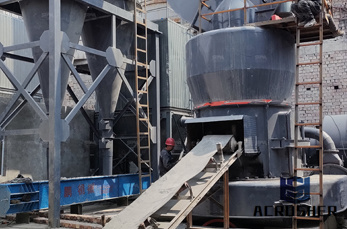

Schematic of design hammer mill 1Main frame,2Single phase Electrical motor 1 k Watt, 3Hammer mill housing Image of the fabricated hammer mill Figures uploaded by Hanafi A Radwan

products with improved design. The machine is portable, design to be power operated. KEYWORDS: Design, Fabrication, Laboratory Size Hammer Mill INTRODUCTION Crushing is an integral part of the comminution flow sheet for mineral processing operations and is critical for the preparation of ore for downstream processing.

Hammer Mill Design, You Can Buy Various High Quality Hammer Mill Design Products from Global Hammer Mill Design Suppliers and Hammer Mill Design Manufacturers at Read more. hammer mill designs and plans. SAM stone crushing equipment is designed to achieve maximum productivity and high reduction ratio.

Hammer mill is a common equipment in wood processing factory and wood pellet plant. It serves to crush wood materials into powders so that they can be used to make wood pellet fuel and other wood products. It can process pines, poplar, cedar, bamboo, weed tree, and various fiber materials like rice straw, cotton stalk, twitch grass, etc. Hammer mill applies to materials whose diameter is 10

WhatsApp)

WhatsApp)