An Investigation of the use of Stearic Acid as a Process

An Investigation of the use of Stearic Acid as a Process Control Agent in High Energy Ball Milling of NbAl and NiAl Powder Mixtures

WhatsApp)

WhatsApp)

An Investigation of the use of Stearic Acid as a Process Control Agent in High Energy Ball Milling of NbAl and NiAl Powder Mixtures

the control loop will attempt to add water to Cyclone 1 sump to achieve a particle size of 15%+ 300 #181;m. If the hardness of the ore increases, the particle size in the mill discharge from ball mill 1 will increase. With the same water addition to sump 1 the particle size of Cyclone 1 overflow will increase. This will decrease the ratio, and hence

13/12/2015#0183;#32;In most processes, there are six basic control elements are 1. Controlled variable What you want to control (temperature pressure, level, flow rat, dimensions, position, etc.) 2. Measured variable What you observe in order to determine the actual condition of

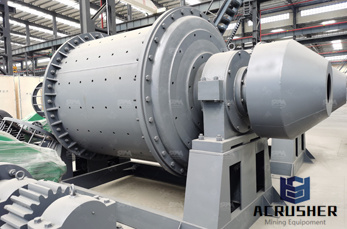

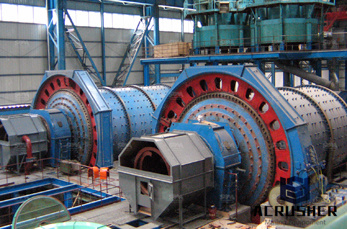

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

Stearic acid seems to be a commonly used process control agent in ball milling. I am wondering what is considered the best approach for separating it out after processing? View

commonly used control strategies are analyzed and discussed. Keywords: Ball mills, grinding circuit, process control. I. Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics.

of the process as a higher distance allows a higher kinetic energy and therefore stronger impacts. Eects of milling on the properties of cellulose Ball milling has a high in uence on the microscopic and macroscopic properties of the resulting material a er treatment, such as structure, morphology, crystallinity and thermal stability.

In fact, choosing the right ball mill depends on the objectives of the process and the sort of materials (hard, brittle, ductile, etc.) that will be subjecting to the ballmilling process. For example, the characteristics and properties of those ball mills used for reduction in the particle size of the starting materials via topdown approach, or socalled mechanical milling (MM process), or

Process IQ offers MillStar Advanced Process Control to stabilise mill feed, discharge and optimise the circuit. TriSlicer, MillSlicer, Ball MillScan, Cement MillScan and Coal MillScan mill vibration technology help reduce liner wear, Ultrasonic density probes provide robust high frequency measurements and CyLas hydrocycle underflow flare provides optimised classification and detect any roping.

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many

A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . process Tip of iceberg . Reference

possible by addition of a PCA. PCAs are added to powder mixtures during the milling to. reduce the effect of cold welding16. In this research, various PCAs including an organic acid, isobutyl alcohol (C4H10O) and Altrisec butylate Al(C4H9O)3, a polymer and a low temperature sublimating.

An Investigation of the use of Stearic Acid as a Process Control Agent in High Energy Ball Milling of NbAl and NiAl Powder Mixtures Characterization of HighEnergy Ball Milling of Ba Hexaferrite

Highenergy ball milling is a ball milling process in which a powder mixture placed in a ball mill is subjected to highenergy collisions from the balls. Highenergy ball milling, also called mechanical alloying, can successfully produce fine, uniform dispersions of oxide particles in nickelbase super alloys that cannot be made by conventional powder metallurgy methods.

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

Process Computer System Development at BougainviUe . Of the twelfth ball mill to perform all control, interlock ing and sequencing associated with mill a second operator station was also added at this stage the system was steadily expanded in subsequent years to perform reagent addition control, mill control and monitor ing, tailings water recovery control and monitoring, and.

Grinding in Ball Mills: Modeling and Process Control

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account. As well, mills with different

WhatsApp)

WhatsApp)