How to grind a Concrete Trip Hazard, Fix Raised Concrete

Mar 13, 2013#0183;#32;for more how to concrete videos to for providin...

WhatsApp)

WhatsApp)

Mar 13, 2013#0183;#32;for more how to concrete videos to for providin...

It is a finely ground powder made by burning and grinding a limestone mixed with clay or chemistry of cement is very complex, so cement chemist notation was invented to simplify the formula of common oxides found in cement.

This review found that the suitable temperature for burning is within the range of 500700#176;c and grinding effect is within 90120 minutes to produce a better result for pozzolanic index.

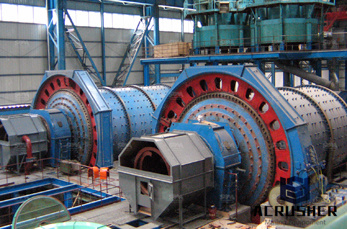

There are three procedures of the cement grinding plant: raw material preparation, clinker burning and cement making. The production technology of the silicate cement is regarded as the representative one in the cement industry. It uses the limestone and clay as the main raw materials which are crushed, dosed and ground to be the primary raw

Portland Cement is made primarily from a combination of a calcareous material, such as limestone or chalk, and of silica and alumina found as clay or manufacturing process consists essentially of grinding the raw materials into a very fine powder, mixing them intimately in a predetermined proportion, and burning them in a large rotary kiln at a temperature of about 1400 C 2550 F.

A cement production plant consists of the following three processes: Raw material process, clinker burning process and finish grinding process. The raw material process and the clinker burning process are each classified into the wet process and the dry process. The major

Cement Extraction and processing | Britannica

Cement Manufacturing Process Mixing of raw materials. The raw materials such as limestone or chalk and shale or clay may be mixed either in dry... Burning. In modern technology of dry process, the coal brought from the coal fields is pulverized in vertical coal mill... Grinding. The clinkers as

It is generally added in very small amounts (about 2% by weight) to the burnt cement (called Clinker) after it is taken out from the kiln and before it is sent for grinding. Gypsum is a sedimentary rock having a composition of calcium sulfate (Ca SO 4 . 2 H 2 O).

However, controlling the burning process can improve the quality of ash produced to effectively use it in cementbased materials. Hence, this research was aimed at exploring the pozzolanic properties of corn stalk ash upon calcination and grinding, for it to be used in the manufacturing of sustainable cement

The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 C.

The percentage consumption of energy in each operation is and % (burning), % (milling), and % (crushing), and 0% (agi tation), and % (grinding), and and % (bagging) of the total energy inputs for the wet and dry proc esses respectively.

Following three distinct operations are involved in the manufacturing of normal setting or ordinary or Portland cement: Mixing of raw materials Dry Process; Burning; Grinding; Mixing of raw materials. The raw materials such as limestone or chalk and shale or clay may be

Cement Cement History of cement: The origin of hydraulic cements goes back to ancient Greece and Rome. The materials used were lime and a volcanic ash that slowly reacted with it in the presence of water to form a hard mass. This formed the cementing material of the Roman mortars and concretes of more than 2,000 years ago and of subsequent construction work in western Europe.

Burning And Grinding Of Cement. We have Burning And Grinding Of Cement,Another essential raw material is gypsum some 5 percent of which is added to the burned cement clinker during grinding to control the setting time of the cement portland cement also can be made in a combined process with sulfuric acid using calcium sulfate or anhydrite in place of calcium carbonate

Burning conventional fuels in cement plants 13 November 2020 This week Cemtech hosted its Live Webinar ''Conventional kiln fuels preparation, storage, firing and safety'' with presentations covering the design and safety of coal mills, a new kiln burner and a project to optimise a petcoke mill.

Manufacture of cement Crushing and grinding. All except soft materials are first crushed, often in two stages, and then ground, usually in a... Blending. A first approximation of the chemical composition required for a particular cement is obtained by selective... Burning. The earliest kilns in

There are four stages in the manufacture of portland cement: (1) crushing and grinding the raw materials, (2) blending the materials in the correct proportions, (3) burning the prepared mix in a kiln, and (4) grinding the burned product, known as clinker, together with some 5 percent of gypsum (to control the time of set of the cement).

May 19, 2020#0183;#32;Manufacture of cement consists of mixing, burning, and grinding processes. 1. Mixing: It may be a wet process or by dry process. In a wet process wash mill is used which is a heavy cylinder of 2. 2. Burning: Burning is carried out in a rotary kiln, which is a steel tube of diameter to m

Portland cement, binding material in the form of a finely ground powder, usually gray, that is manufactured by burning and grinding a mixture of limestone and clay or limestone and inventor Joseph Aspdin, of England, patented the basic process in 1824, naming it for the resemblance of the cement when set to portland stone, a limestone from the Isle of Portland.

WhatsApp)

WhatsApp)