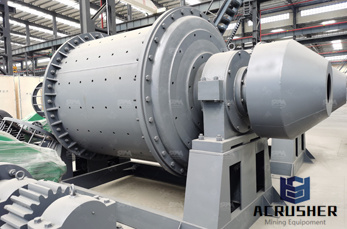

Grinding Mill

The FUTURE of Grinding Industry is HERE! Strong production bases guarantee the normal production of grinding mills and quick is SBM POWER!

WhatsApp)

WhatsApp)

The FUTURE of Grinding Industry is HERE! Strong production bases guarantee the normal production of grinding mills and quick is SBM POWER!

It grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the ball mill machine. The larger the

Cement making process great wall corporation the clinker is finely ground with about 5% gypsum in another ball millproducing cement(the gypsum regulates the early setting characteristic of cement)the finished cement is stored in silos then carted to our wharf or packing plant facilitiessome facts and figures the mills for grinding the raw materials are 24m in diameter and 110m

As the tube rotates, the balls tumble onto the coal,crushing and pulverizing it. Impact Mills Grinding Action is carried out by aseries of. Ball Mill for Gypsum,Limestone,Cement,MineralFruitful. Dec 09, 2014#183; Want to buy ball mill, please contact email:[email protected] Fruitful/products/beneficiation/ Ball mill is a key equipment to

Apr 01, 2016#0183;#32;The properties of the micronized gypsum products obtained were determined, among which the best set of results was obtained with 80% of critical speed (85 rpm) for operation speed, as the ball filling ratio (J b), 20% (2 cm), 60% (3 cm) and 20% (4 cm) as the ball size distribution, as the powder filling ratio (f c), % of powder as the grinding aid ratio, and a grinding time of 30 min,

Application of Gypsum Ball Mill: It is a kind of key equipment for milling the materials into powders after they are crushed. It is widely used for cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics and so on, and can make the dry and wet milling on all kinds of ores and other grindability materials.

china ball mill / ball mill for cement / gypsum ball mill_Product Search. Ball Mill is mainly used to grind materials in mineral cement refractory chemical industry etc. Ball Mill has dry and wet wet Ball Mill works certain water and other liquid will be added into materials to increase flowability of materials so the capacity is increased.

Alumina Grinding Cylinders. Mill Linings. The alumina lining brick works as the lining in the ball mill, widely used in ceramic industry, cement industry, chemical industry, medicine industry and coating industry. The brick improves the grind. More. Previous page 1 Next page Go to No. Need to consult

Cement milling and gypsum dehydration Because the cement gets hot due to the heat generated by grinding, gypsum can be partly dehydrated, forming hemihydrate, or plaster of Paris 2CaSO 2 O. On further heating, hemihydrate dehydrates further to a form of calcium sulfate known as soluble anhydrite (~CaSO 4).

Gypsum Ball Mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and rippleliner and different specifications of steel balls in the chamber.

Shanghai Clirik is The Most Prefesional Gypsum Grinding Mill Maunfactureamp;Supplier in China,The Main Products include Gypsum Ultrafine Grinding Mill,Gypsum Raymond Mill,Gypsum Ball Mill,Gypsum Hammer Mill,GypsumCrusher and so on.

gypsum grinding mill manufacturer in Shanghai, China. gypsum grinding mill is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions. Shuliy lab biomass grinder mill 0086 View lab

Apr 01, 2016#0183;#32;The grinding machine was a laboratoryscale ball mill made of stainless steel with the dimensions 200 #215; 200 mm. The grinding media were stainless steel balls with a density of kg/m 3 and with three different diameters (, 2, 3, and 4 cm). Powder density was found to be g/cm grinding experiment was performed as a batch process; after each test, all media and ground

Alumina micro powder grinding mill. Alumina also be called as Bauxite, is an aluminium ore and is the main source of aluminium. Alumina processing: PC hammer crusher, PE jaw crusher, YGM series high pressure grinding mill, and HGM series micro powder grinding mill are usually used in alumina processing system.

Temperature control. Heat generated in the grinding process causes gypsum (CaSO 4 .2H 2 O) to lose water, forming bassanite (CaSO 4 . 2 O) or anhydrite (CaSO 4 .~ 2 O). The latter minerals are rapidly soluble, and about 2% of these in cement

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 2040% water by weight.

How Gypsum Grinding Ball Mill Works; how gypsum grinding ball mill works how gypsum grinding ball mill works. Sbm New Goods Latest Price Limestone Raymond Mill Pulverizer, raymond mill is commonly used grinding plant, which is mainly used for the, activity white soil, activated carbon, kaolin, cement, phosphorus ore, gypsum, . /pics/ An

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral Ball mills are used extensively in the Mechanical alloying

The uses of gypsum grinding mill: gypsum ultrafine grinding mill is mainly used in mining, building materials, chemical, metallurgical and other industries. It can process stone materials that moisture content less than 5%, Mohs hardness under 6 levels, such as kaolin, limestone, talc, barite, dolomite, calcite, marble, gypsum, bentonite, mica

Gypsum grinding mill is the preferred stone machining equipment. Working principle of gypsum grinding mill: The main bearing and each dial are driven by electromotor of main machine through reducer, and numbers of rollers, which are rolling in the ring, are driven by dial through plunger.

Main equipment: LM170K vertical mill; Process Flow Of Gypsum Grinding Line. LM vertical roller mill a comprehensive, largescale grinding equipment that integrates the five functions of crushing, grinding, powder selection, drying, and material conveying. The LM vertical mill integrates crushing, drying, grinding, powder selection, and conveying.

WhatsApp)

WhatsApp)