Gold Metal refining amp; Recovery || gold purifying process

Jun 13, 2019#0183;#32;Welcome to AMAZING CREATIVITY WORK Gold Metal Refining amp; Recovery,Gold Purifying Process Gold Refining Process||Gold Refinery HOW TO KNOW GOLD IS REAL AND FA...

WhatsApp)

WhatsApp)

Jun 13, 2019#0183;#32;Welcome to AMAZING CREATIVITY WORK Gold Metal Refining amp; Recovery,Gold Purifying Process Gold Refining Process||Gold Refinery HOW TO KNOW GOLD IS REAL AND FA...

May 11, 2020#0183;#32;The Miller process is a gold refining process that produces gold of approximately % purity, sufficient for many applications. It is faster and less costly than other refining options used to produce purer gold

With Millers process of refining impure gold with chlorine gas (patented in Britain in 1867) and Emil Wohlwills electrorefining process (introduced in Hamburg, Ger., in 1878), it became possible routinely to achieve higher purities than had been allowed by fire refining. Ores

Gold electrolysis is the second, good method used in goldmaking industries to separate gold from the other metals. This procedure has been noted to produce gold that is almost % pure. The principle and equipment for gold electrolysis. Gold electrolysis was invented by Emil Wholwill in 1874.

The Miller process is an industrialscale chemical procedure used to refine gold to a high degree of purity (%). It was invented by Francis Bowyer Miller (patented 1867). This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten, but impure, gold.

The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold. The Miller process is rapid and simple, but it produces gold of only about percent purity. The Wohlwill process increases purity to about percent by electrolysis. In this process, a casting of impure gold

Metallurgical ContentRefining of Gold Obtained by Other Processes (Amalgamated Gold)Pan AmalgamationCopper Plate AmalgamationPurifying MercuryPurifying AmalgamRefining Retorted Gold The purification of such alluvial gold alloys is a simple matter. The high specific gravity of the metal allows of separation from most admixed materials by some process of elutriation, or water

In gold processing: Refining commonly employed for purification: the Miller process and the Wohlwill process. The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous chlorine more readily than gold does at temperatures equal to or greater than the melting point of gold.

Jan 18, 2017#0183;#32;The most common gold refining methods include: 1. Miller Process . This is a chlorination process that refines gold to a purity of about %. The process involves blowing chlorine bubbles through molten gold which reacts with metallic impurities forming a chloride slag that is separate from pure gold and floats on top.

authority on gold metallurgy, and the chlorine refining process was chosen specifically with a view to the rapid and effective treatment of large amounts of bullion. This process had been patented by Miller, Assayer of the Sydney Mint, in 1867 and used in Australia since 1872 in contrast to the Lon#173;

#173;The final stage of gold production refining involves removing impurities that remain after the smelting companies receive dor#233; bars, as well as scrap gold, and reliquefy the metal in a furnace. Workers add borax and soda ash to the molten metal, which separates the pure gold from other precious and less precious metals. A sample is then taken to a lab for tests, or

5K to 10K gold: Melt your 5K 10K gold and cast an ingot. Place the gold ingot in the unit, fill the unit with electrolyte and turn on the power supply. 1224 hours later, remove the anode section and wash the gold with water. Remove the disposable ashless paper bag with refined gold

miller process gold refining machine. How to Refine Gold: 2 Major Techniques of Gold . It is an electrochemical process which has been applied in many largescale goldrefining establishments or industries. The principle of gold electrolysis is very straightforward or simple: Dore bar, which is a cast gold ingot at 95% plus purity is used as

Unlike the Wolhwill Process described earlier in this series the Miller Process doesnt use electricity but rather uses a stream of chlorine gas that is passed through a crucible of molten gold that produces gold that is Fine. It works to remove all the impurities because gold is least affected by chlorine so all the other impurities are removed as chloride slag floating on the surface of the molten gold where it is

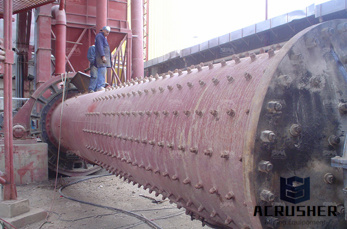

Mill Machining, Milling Process, Horizontal amp; Vertical Milling Machines Definition. Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one can perform many operations and functions starting from small objects to large ones.

Gold Refining Purification Process. Gold Recovery Process From Scraps. Keep up to date with the latest metalsmithing news and release of new jewelry making tutorials. Yes, subscribe me. This is a free tutorial on gold recovery method using nitric acid to extract pure gold from old gold and scraps of gold by process of dissolving unwanted metals.

Miller Welding Equipment is renowned around the world for the colour quot;Bluequot;. Our Miller range includes new, used and refurbished stick welders, TIG and MIG welding machines, multiprocess power supplies and Miller diesel welder generators.

The solubility of gold in a water and cyanide solution was discovered in 1783 by Carl Wilhelm Scheele, but it was not until the late 19th century, that an industrial process was expansion of gold mining in the Rand of South Africa began to slow down in the 1880s, as the new deposits being found tended to be pyritic gold could not be extracted from this compound with any

WhatsApp)

WhatsApp)