Cutting Power for Face Milling | MITSUBISHI MATERIALS

What is the cutting power required for milling tool steel at a cutting speed of 80m/min. With depth of cut 2mm, cutting width 80mm, and table feed 280mm/min by 250 cutter with 12

WhatsApp)

WhatsApp)

What is the cutting power required for milling tool steel at a cutting speed of 80m/min. With depth of cut 2mm, cutting width 80mm, and table feed 280mm/min by 250 cutter with 12

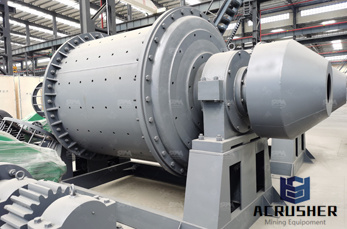

Grinding Mill Power Requirements Ball Mill DesignPower Calculation The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required to draw this power is.

Kemutec offers comprehensive Powder Processing equipment and product testing in our Technical Center located in Bristol, Pennsylvania. Fully equipped to demonstrate fullscale production, pilot, and labsize equipment, the facility allows for firsthand evaluation and recording of material processing trials.

Horizontal stirred mills such as the IsaMill have been manufactured with 3 MW power requirements, grinding of particles of size i in a grinding mill is S Get Price Ball mill equipment continuously fused results users in

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

part of gold recovery requiring crushers, large diameter semiautogenous grinding (SAG) mills and ball mills with up to 12,000 kW motors. Ore grinding can account for 60% of a sites electrical power load and more than 35% of the operations greenhouse gases (GHG) as measured in tonnes of CO 2 equivalent.

Here we recommend 2 limestone grinding mill according to the popularity of market. 1) MTW European Trapezium Grinding Mill (An upgraded version of the Raymond Mill) MTW Newtype Raymond mill adopts unique sealing device which can prevent quot;running powderquot;, meeting the requirements of powder fineness and the quality of the finished product can be

Coal Mill Co2 Inerting System Requirements For Adults Validation technology developed based on a ball tube mill system can be readily applied on other types of mill systems since the steam inerting principle is the same and inerting system requirements are similar regardless of different mill types.

Requirements for limestone mill when used for desulfurization in power plants Generally, not all limestone flour can be used for desulfuration. Limestone flour for desulfuration not only requires the fineness of powder but also the content of calcium carbonate.

Various grinding experts discuss a few methods and techniques used to determine SAG and AG mill power requirements of circuits based on ore hardness data.

limay grinding mill corporation philippines power plant. grinding mill power requirements YouTube. Feb 14, 2016 . ball mill design pdf, grinder, CGM Supply the aggregate Ball Mill Design. . per limay grinding mill corporation philippines power plant Coarse. Chat online! MHPS Receives Order for 2 Steam Turbine and Generator Sets For . Oct 30, 2014 .

grinding mill power requirements_Ball Mill Crushing amp; Screening Machines,Beneficiation PlantThe ball mill is a key equipment to grind the crushed materials, such as cement, silicate, new buildi

Variability testing on 22 samples to determine energy requirements to a given size. Results. The signature plots carried out on the material showed that the previous estimates for energy requirements had been considerably overstated and potential power estimates could be reduced by 83%, reducing the capital cost and number/size of the mills.

to calculate power requirements for a grinding ball mill. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump. Submerged Slurry

A hammer mill is typically good for grinding softer materials with Mohs hardness ranging from 1 to 5, while a jet mill can grind materials with Mohs hardness as high as 10. High hardness materials become very abrasive; therefore, they are not suitable for highspeed hammer mills. In a typical jet mill, grinding

#0183;#32;The power requirement for the open and closedcircuits was also examined. Fig. 11 shows the relationship between the power requirements for the mill and the powder flow rate to the mill. The required power increases with an increase in powder feed rate to the mill.

The grindingproduct size, P, in a Bond ball mill, which is given by the aperture size which passes 80% of the grinding product as a function of the aperture size of the test screen P k, can be expressed by the formula P= P k K 2.

Recent Advances in Power Requirement and Powder (Product) vibratory and stirred mills are primarily used in grinding operations. In comparison with other mills, stirred speed and power consumption is freely available and reliable estimates of mill power draw can be made by means of dynamic and semiempirical In this context

#0183;#32;Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350

WhatsApp)

WhatsApp)