(PDF) DESIGN AND FABRICATION OF MINI BALL MILL

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

WhatsApp)

WhatsApp)

This project is to design and fabricate the mini ball mill that can grind the solid state of various type of materials into nanopowder. The cylindrical jar is used as a mill that would rotate the

differentiation between ball mill machine grinder; indian wet grinder; small grinding mill for cement making; hand mill grinder ebay electronics, cars, fashion . #187; Learn More difference between milling and grinding

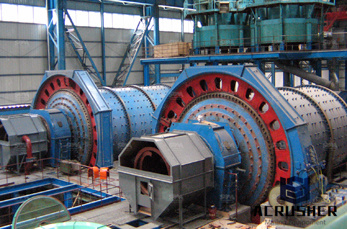

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

#0183;#32;The Ball and Rod Mill type LMBRM is a process and laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard and brittle materials in dry and wet phase.

differentiation between ball mill machine grinder. grinding machine, coal crusher, wet grinder, vertical 0 5 mn tonne grinding capacity is how much cement capacity, parle project brand representation of parle . Read more; differentiation between mill machine grinder.

This machine is equipped with a small cooling chamber that houses a rotor stator configuration that is designed with very close tolerance between them. The interior of the chamber is close to the stator minimizing the interior space, and the compact area allows for the product to have little space to move around forcing it be fed through the rotor stator as it shears the materials.

What''s the Difference Between SAG Mill and Ball . Difference Between SAG Mill and Ball Mill, from the working principle, application, structure, etc. Grind and blend solid or hard materials into smaller pieces by means of shear, impact and compression. What are the differences between ball mill and rod

#0183;#32;A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

The ball mill and the rod mill are the same type of machine on the appearance, but there are still great differences in the interior. It is very necessary to select a suitable machine for the production to optimize the product effect and maximize its efficiency.

Air classifying mills or jet mills can be suitable for ultrafine grinding and when you want to mill your foods to submicron levels we can help you with ball mill solutions. And when you are trying to reduce the particle size of a solid in suspension in a liquid, you may benefit from colloid or

Ball mill and rod mill are the common grinding equipment widely used in the mineral processing plant. They are similar in shape and grinding principle, but also different in structure, performance and application. Here are seven differences between ball mill and rod mill to tell you how to choose the ball mill and rod mill.

Difference Between Sag Mill vs Ball Mill mech4study. Oct 12, 2017 #183; Today we will learn about difference between sag mill vs ball mill. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting.

We discuss the types of ball mill, the basic principles of the ball mill, how it works, the details of design including equations for optimum dimensions in all cases, some manufacturers for the ball mill, and estimation of the cost the ball mill. 6. 1. Introduction Ball mill is an efficient tool for grinding many materials into fine powder.

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

What are the differences between ball mill and rod mill The ball mill and the rod mill are the same type of machine on the appearance, but there are still great differences in the interior. It is very necessary to select a suitable machine for the production to optimize the product effect and maximize its efficiency.

The main differentiation factor between tube mill and ball mill is the _____? The main differentiation factor between tube mill and ball mill is the _____? A. Length to diameter ratio B. Size of the grinding media C. Final product size D. Operating speed. Mcq Added by: Muhammad

The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into account. As well, mills with different

The difference between vertical roller mill and ball mill The ball mill is generally composed of a horizontal cylinder, a hollow shaft for feeding and discharging, and a grinding head. The cylinder body is provided with an abrasive body, the cylinder body is made of steel plate, and the steel lining plate is fixed with the cylinder body, and the grinding body is generally a steel ball, and

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

Energy Saving Ball Mill * Product Introduction A high efficiency and energy saving ball mill with rolling bearing * Capacity Up to 160t/h * Product Improvement Cylindrical energy saving grid ball mill is lined grooved ring plate which increases th...

WhatsApp)

WhatsApp)