(PDF) CURRENT TRENDS IN SAG AND AG MILL

However, AG/SAG grinding circuits are quite sensitive to the mix of fine and coarse material in the mill feed. This paper explores the relation between fragmentation size and grinding circuit

WhatsApp)

WhatsApp)

However, AG/SAG grinding circuits are quite sensitive to the mix of fine and coarse material in the mill feed. This paper explores the relation between fragmentation size and grinding circuit

ball mill cost in brazil; mobile crusher plant flow sheet 22870; biggest crusher plant in indonesia; mining detection equipments in iron ore; axminster sieg x mini milling machine micro mill belt conversion; machinery on construction site; rock crusher rd church of christ crystal river fl; casting grinding balls for sag mill principle.

vertical mill operating principle unicjeanmonnet . Vertical mill principle of operation crazycarsteam . SAG mill operating principles CGM Grinding Plant. Mill (grinding) Wikipedia, the free encyclopedia. It is similar in operation to a SAG mill as described below but does not use steel balls in the mill. Get Quote. Get Price gt;

Fully autogenous circuits are attractive due to the elimination of steel media costs. Typically, a SAG mill based circuit (P80 of 106 to 150 um) has media costs of around A1/t. Providing the ore is amenable, the use of primary autogenous milling can reduce this cost by 40%. Autogenous milling is typically practiced in association with

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls. Then, discharge of ground material performed

Choosing a SAG Mill To Achieve Design Performance John Starkey1, Principal Consulting Engineer Sami Hindstrom2, Manager, Grinding Travis Orser2, Project Manager, Grinding 1 Starkey amp; Associates Grinding Design and Process Engineering 336 268 Lakeshore Rd. E. Oakville, Ontario L6J 7S4

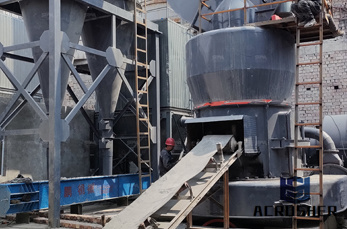

SAG Mill Semi autogenous grinding (SAG)technology, as an effective measure to reduce the capital investment and production cost, has been widely recognized. It has been widely applied in nonmetal mineral processing, ferrous metal mineral processing and nonferrous metal mineral processing, and is being popularized gradually in gold processing plant.

working principle of sag and ball mill. the working principle of ball mill. Working Principle of Ball MillLinkedIn. The actual ball mill working principle is much more complicated than the above discussion the expansion of the particles on the surface crack and the new crack will appear for each particle crack interaction in the second level of crushing the interaction between particles

The mill discharge from these mills consists of slurry, which goes to the ball mills for further grinding, and coarse pebbles/rocks, which are crushed and sent back to the mill. To maximize the capacity of these circuits, the general practice is to use grates with pebble ports (reaching 100 mm) instead of normal grate openings to increase the pebble removal.

Principle of SAG Mill operation. SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. Related items: Mortar and pestle, Expeller, Extruder; PAI SAG Mill Training YouTube

Oct 12, 2017#0183;#32;SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

We offer autogenous (AG), semiautogenous (SAG), ball, rod, and pebble mills in sizes ranging from kWs up to 30+ MW. Our product range also includes a number of unique solutions, including the worlds largest acidresistant grinding mills, which can operate with extremely corrosive slurry.

PDF | On Sep 1, 2001, S. Strohmayr and others published SAG mill circuit optimisation at Ernest Henry Mining | Find, read and cite all the research you need on ResearchGate

Get principle operation of sag mill Price. You can get the price of principle operation of sag mill and a Aamp;C representative will contact you within one business day. ball mill working principle YouTube. #183; molino sag Duration: 6:34. Cafimec 45,541 views. 6:34 . Building a DIY Solar Generator for 650 Start to Finish

Oct 12 2017 today we will learn about difference between sag mill vs ball mill a mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding crushing or cutting this commutation is an essential part of many proce Working principle for ball mill.

The relining of mills is a necessary process and it is very often the critical maintenance path of a concentrator shut down. Generally speaking, and depending on current ore prices, the production of a large SAG mill usually equates to between US30,000 and US200,000 per hour.

SAG is an acronym for semiautogenous grinding. SAG mills are autogenous mills that also use grinding balls like a ball mill. A SAG mill is usually a primary or first stage grinder. SAG mills use a ball charge of 8 to 21%. [6] [7] The largest SAG mill is 42 () in diameter, powered by a 28 MW (38,000 HP) motor. [8] A SAG mill with a 44

#0183;#32;The SAG Mill is a machine added by Ender uses Micro Infinity (#181;I) to grind (or mill) items into their crushed variants, like Ores into SAG Mill has four output slots; recipes can have 14 different outputs, with different chances of obtaining those outputs. Uniquely, the SAG Mill can use Grinding Balls made from various materials to increase energy efficiency (resulting in

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. T

SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is

Aug 17, 2018#0183;#32;SemiAutogenous Mills/ SAG Mills (primary grinding mill) these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in

The SAG Mill is a block added by the EnderIO mod. A machine similar to a Pulverizer or a is used to process resources to produce dust. It accepts energy in the form of Redstone Flux or Minecraft Joule, with an internal buffer of 100,000 RF and consumption of 20 RF per energy storage capacity and processing speed can be increased by adding one of 3 tier of Capacitor into

WhatsApp)

WhatsApp)