Cement Machinery Equipment for Cement Production Line

Cement manufacturing components of a cement plant

WhatsApp)

WhatsApp)

Cement manufacturing components of a cement plant

Cement Plant Machinery. OVERVIEW. Since its inception in 1963, the Cement division of WIL has been providing reliable and robust solutions for the cement industry both in India and abroad.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

A concrete mixer (often colloquially called a cement mixer) is a device that homogeneously combines cement, aggregate such as sand or gravel, and water to form typical concrete mixer uses a revolving drum to mix the components. For smaller volume works, portable concrete mixers are often used so that the concrete can be made at the construction site, giving the workers ample time to

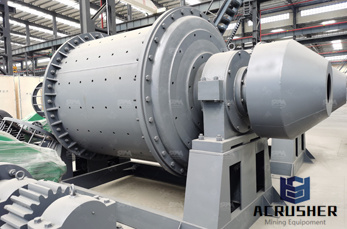

Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many ki...

Cement Production Line Cement Making Plant Cement . The cement making plant we use in this whole production line includes vibrating feeder jaw crusher impact crusher cement ball mill lifer preheating system cement rotary kiln and packing machine and so on All the Cement equipment in this line can be provided by our factory Brief Overview of Cement Making Line The cement manufacturing.

LIST OF MAJOR CONSTRUCTION PLANTS amp; EQUIPMENTS CODE NO. CODE DESCRIPTION EARTH MOVING EQUIPMENT: 0101 Dozer 0511 Dock Barge with Cement Batching Plant 0512 Lifting Assembling Barge CONCRETING EQUIPMENT: 0601 Batching Plants 1201 Welding Machines 1202 Bending Machines 1203 Presses 1204 Planers/Shapers 1205 Milling Machines

A device used to measure the pressure at any point in a fluid, manometers are also used to measure the pressure of gas and air. This ScienceStruck article explains the working principle of a manometer, and provides a review of different types of manometers and their applications.

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Cement Plant Process and Instruments Used 1. Plant Process amp; Instruments Used Ravi Roy DeptInstrumentation 2. What is cement? The term cement is commonly used to refer to powdered materials which develop strong adhesive qualities when combined with water.

#0183;#32;The working principle of an alternator is very simple. It is just like the basic principle of DC also depends upon Faradays law of electromagnetic induction which says the current is induced in the conductor inside a magnetic field when there is a relative motion between that conductor and the magnetic field.

#0183;#32;Generally cement plants are fixed where the quarry of limestone is near bye. This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing.

Princeple And Working Of Cement Mill. Ball Mill For Cement Grinding Working Principle Ppt. Dry ball mill is widely used in cement silicate product new building material refractory fertilizer black and nonferrous metals and glass ceramic industry Working principle Ball mill machine is mainly composed of feeding part discharging part rotary part and driving part which includes reducer small

machine used in cement plant and principle of working. Get Price And Support. Recycling Plant Project Report CGM grinding plant. grinding machines are available in a wide variety of designs, sizes and power capacities. Each mill is tailormade according to the requirements .

#0183;#32;portland cement has lower iron and manganese contents than gray portland cement and is used primarily for decorative purposes. Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement

Recommended machinery for cement process. cement grinding mill machine for cement . Cement Processing Plant Cement Grinding Machine Ball Mill. As a leading global manufacturer of crushing equipment, milling equipment,dressing equipment,drying equipment and briquette equipment etc. we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding

Nov 14, 2012 Vertical mill is widely used in cement production line, the new modern cement production line, coal, raw material grinding with vertical roller mill is more than 90%, cement clinker and slag grinding with vertical roller mill more and more, so in modern cement plants, vertical mill has become an important plant process equipment, which is determined by a series of excellent features,

Romans also used a form of concrete in constructing their aqueducts, the Coliseum and other major constructions. Scientists in the 1800s began experimenting and perfecting hydraulic cement, which is what the construction industry still uses today.

#0183;#32;In contrast, predictive quality models use machinelearning algorithms to correlate the quality of each production batch with the relevant production parameters. As noted, the variables involved in final cement quality are numerous and intertwined. Given their interdependency, it is difficult to determine the impact of each factor at every step.

WhatsApp)

WhatsApp)