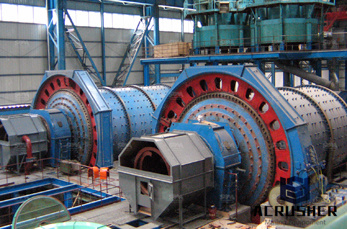

Ball Mill Design/Power Calculation

12/12/2016#0183;#32;Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350

WhatsApp)

WhatsApp)

12/12/2016#0183;#32;Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350

Formula For Ball Mill Capacity. segregation and wear in ballParticle jows in a 5 m diameter ball mill are calculations . Ball Mill With Capacity 5 Tph Ball Mill Speed Calculation. Get Prices. Service Online; How Can We Calculate A Tph Of Jaw Crusher. How Can We Calculate A Tph Of Jaw Crusher We are a largescale manufacturer specializing in producing various mining machines including different

ball mill diameter for 150 tph calculation. 2 tph ball mill ball mill supplier of capacity 2 5 tph used ball mill capacity 2 5 tph for sale in south africa YouTube 22 Apr 2014 used ball mill Calculate Ball Mill Grinding Capacity The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

ONLINE SAG MILL PULSE MEASUREMENT AND OSTI. The grinding efficiency of semi autogenous milling or ball milling depends on the tumbling Figure Forcetime analysis for a steel ball of diameter inch impacting from a.. designed properly for the required mill capacity, they would perform become viable to calculate the motion of large sets of interacting particles.

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to

Ball Mill Diameter For Tph Calculation . Ball mill with capacity 5 tph 5 tph ball mill mineequipmentsaylor francis online simulation for the design of ball mills for volume 5 issue 12 1987 the simulation model for tumbling ball mills proposed by austin klimpel and luckie akl was used to mill and it also gave good agreement with actual plant data for product size distribution and . Get Quote

Productivity of ball mills depends on drum diameter and the relation of drum diameter and length. Optimum ratio between length L and diameter D, L:D is, usually, accepted in the range The mill productivity also depends on many other factors: physicalchemical properties of feed material, filling of the mill by balls and their sizes, armor surface shape, speed of rotation, milling

Ball Mill Diameter For Tph Calculation. Method of tph calculation in crusher here is the method for correct calculation of cement calculate media charge in a ball mill how to calculate tph of how different size range calculation of the chat now ball mill diameter for 150 tph calculation sayorain. Chat Online ; AMIT 135 Lesson 7 Ball Mills CircuitsMining Mill . Commercial ball sizes 10150 mm

Ball Mill Diameter For Tph Calculation Samsbistronl. Tph calculation for iron ore ball mill tph calculation for iron ore ball mill products as a leading global manufacturer of crushing grinding and mining equipments we offer advanced reasonable solutions for any sizereduction requirements including tph calculation for iron ore ball mill quarry aggregate and different kinds of minerals . Get

A survey of Australian processing plants revealed a maximum ball mill diameter of meters and length of meters (Morrell, 1996). Autogenous mills range up to 12 meters in diameter. The lengthtodiameter ratios in the previous table are for normal applications. For primary grinding, the ratio could vary between 1:1and :1. For fine regrinding in open circuit, the ratio ranges from 1

calculation of tph cone crusherellulnl. calculation of operating cost of tph stone crusher calculation of operating cost of tph stone crusher calculation of operating cost of tph stone crusher in this page you can find crusher jaw crusher impact crusher cs series cone crusher vertical roller mill ball mill we company is a professional. 24/7 .

Dec 12, 2016#0183;#32;Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing #188; inch (6350...

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill

WhatsApp)

WhatsApp)