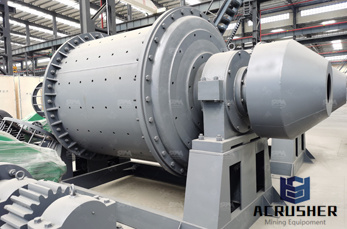

Airswept coal mill|Coal mill|Coal grinding millBuilding

Raw Materials: coal, cement, raw ore, calcite, cement clinker, dolomite, clay, coal gangue, barite

WhatsApp)

WhatsApp)

Raw Materials: coal, cement, raw ore, calcite, cement clinker, dolomite, clay, coal gangue, barite

Today, it is estimated that the global steel industry used about 2 billion tonnes of iron ore, 1 billion tonnes of metallurgical coal and 575 million tonnes of recycled steel to produce about billion tonnes of crude steel. Recycled steel (sometimes called scrap steel) is one of the industrys most important raw materials.

Coal Hammer Mill Crusher Coal Hammer Mill Crusher. The hammer crusher is one of the main equipment for intermediate and fine crushing the brittle materials with less than intermediate such as limestone coal and other used in metallurgy building material chemical and water power industry with a feature of. Hammer Crusherlvssn Group

on future demand for selected raw materials relative to the historical demand for these materials. The Geological Survey developed estimates of future requirements for raw (and some recycled) materials based on the assumption that wind energy will supply 20 percent of the electricity consumed in the United States by 2030.

Paul Breeze, in Power Generation Technologies (Second Edition), 2014. Cost of coalfired power generation. Coalfired power stations are relatively expensive to build since their construction involves both large quantities of expensive materials, such as iron and steel, and large volumes of labor. While some parts of a coalfired power plant such as its steam turbines can be assembled in a

84 Lumber offers a variety of building materials amp; supplies for your construction needs. Store Locator Store Locator Use My Location. Zip or Store Number Radius. Find Stores. My Store EIGHTY FOUR Store #201. 1019 ROUTE 519 EIGHTY FOUR, PA Get Directions . P:

Applicable materials of airswept coal mill. Cement, coal, The ammonium phosphate, potassium chloride, limestone, graphite, mica, Silicon nitride and so on. Advantages of airswept coal mill. 1. high grinding efficiency, high energy utilization. 2. reliable, continuous operation, large capacity. 3. less transmission parts and less maintenance cost. Working principle of airswept coal mill

use of coal mill in cement manufacturing process Welcome to Shanghai CNC Mining and Construction Machinery Co., Ltd. Manufacturing Process About Cement Cement: Lafarge is a leader in the use of alternative raw materials and fuels for fueling manufacturing coal, for fueling its cement

Large steel mills typically use basic oxygen furnaces (BOFs), which burns coal or natural gas to melt ironore to extract the iron, and then mixes the iron with scraps of iron and steel to make new steel. Most of the inputs to a BOF are mined, raw materials, so the recycled content level for BOFs is

materials of construction for coal mills. material of construction for coal hammer mill. zenith heavy industry is specialized in the design, building material hammer crusher for coal handling plant .

A Strong Foundation. Vulcan Materials Company is the nations largest producer of construction aggregatesprimarily crushed stone, sand and graveland a major producer of aggregatesbased construction materials, including asphalt and readymixed concrete. Our coasttocoast footprint and strategic distribution network align with and serve the nations growth centers.

A pugmill or pug mill is a machine in which clay or other materials are mixed into a plastic state or a similar machine for the trituration of ore. Industrial applications are found in pottery, bricks, cement and some parts of the concrete and asphalt mixing processes. A pugmill may be a fast continuous mixer. A continuous pugmill can achieve a thoroughly mixed, homogeneous mixture in a few

Home []

Metallurgical ContentBall Mill Capacity VS Rod Mill CapacityWorking Principle amp; OperationRod Mill Capacity TableBall VS Rod Mill ConversionTypes of Mill DischargeBall Mill Trunnion and Mill Grate DischargePeripheral Grinding Mill DischargeLoad Capacity of Trunnion BearingsBall Mill amp; Rod Mill LinersGrinding Mill GearsGrinding Mill DrivesBall Mill Grinding CircuitBall Mill SpecificationsAll

Aug 16, 2014#0183;#32;To create a 1,000 Kg of Portland cement, calcium carbonate (60%), silicon (20%), aluminium (10%), iron (10%) and very small amounts of other ingredients are heated in a large kiln to over 1,500 degrees C to convert the raw materials into clinker. The clinker is then interground with other ingredients to produce the final cement product.

WhatsApp)

WhatsApp)