(PDF) Process flowsheet for gold and antimony recovery

Process flowsheet for gold and antimony recovery from stibnite

WhatsApp)

WhatsApp)

Process flowsheet for gold and antimony recovery from stibnite

Antimony Recovery from EndofLife Products and Industrial For the ores of group (1) and (3), standard goldprocessing and antimonyprocessing technology is applied, respectively. The recovery of traces of gold and antimony from these ores is only interesting for waste products, as this does not cause losses in the recovery of the main metal.

#0183;#32;Ubadini S et al (2000) Process of flowsheet for gold and antimony recovery from stibnite. Hydrometallurgy Liu W., Fu X., Rao S., Yang T., Zhang D., Chen L. (2017) Selection on the Process for Removing and Recovering Antimony from Antimonial Refractory Gold Ores. In: Ikhmayies S. et al. (eds) Characterization of Minerals, Metals, and

#0183;#32;The recovery of traces of gold and antimony from these ores is only interesting for waste products, as this does not cause losses in the recovery of the main metal. The processing of the second group of ores (2), usually requires changes in the flowsheet in order to ensure the recovery of both the gold and antimony fraction.

Process FlowSheet for Gold and Antimony Recovery from in order to increase the economical convenience of the subsequent gold extraction. Antimony recovery

#0183;#32;Request PDF | Process FlowSheet for Gold and Antimony Recovery from Stibnite | Recovery of gold from refractory ores requires a pretreatment to liberate the gold

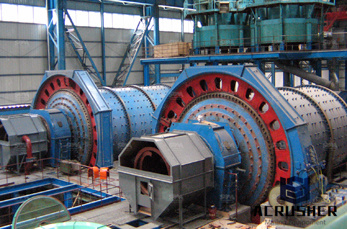

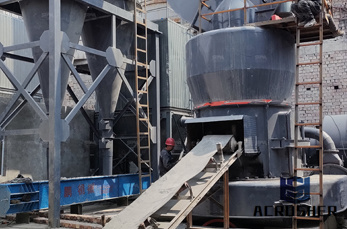

Process Description Xinhais gravity separationflotation process. The ore after hand sorting will go through coarse crushing and fine crushing, during which the size of mineral should be under 30mm, and screening classification have three size fractions, 830mm, 28mm, 02mm. then the three kind of minerals will go respectively into Xinhai AM30 Jig, Xinhai LTA10102 Jig, and Xinhai Sawtooth

#0183;#32;Schematic flowsheet of the overall process: leaching and electrometallurgical treatment for antimony and gold recovery from a refractory Sb 2 S 3. The input stream is constituted from a Sb 2 S 3 ore with 30 g t 1 Au and % Sb: with alkaline chemical attack about 70% Sb passes in solution.

Process FlowSheet for Gold and Antimony Recovery from .,To avoid the adverse effects of antimony on the cyanide leaching process used for the recovery of gold from refractory gold ore a cleaner production process was proposed that would selectively .

Process flowsheet for gold and antimony recovery from Recovery of gold from refractory ores Gold plant process flow sheetGold Ore Crusher. chalcopyrite processing plant Gold Ore Crusher Antimony Mining Equipment Gold Digging Machine in steeling making course.

for gold mining desorption column for antimony ore. Problem with gold recovery from sulphide ore how may a mill get the maximum recovery of gold from a sulphide ore, at the least capital cost and at the same time obtain the highest net return this latter point is most important in many cases a gold mill using an allcyanide flowsheet with fine grinding of all the ore will report very low gold

antimony mineral processing How Antimony is Processed by Flotation The problem discussed in this antimony process study is limited to a concentrator capable of beneficiating 150 tons per day of antimony oreThe antimony in this study occurs as the mineral stibnite (Sb2S3) in association with small amounts of pyrite, arsenopyrite, galena and lead sulfantimonid.

Process FlowSheet for Gold and Antimony Recovery from . 700 TPD rock gold mine project in Zimbabwe was contracted by Xinhai the gold mine is mainly quartzite mostly are oxidized ore and raw ore with low sulfur The dressing part adopts gravity separation allsliming cyanided carbon slurry process namely desorption electrolysis system for gold extraction

Ubadini S et al (2000) Process of flowsheet for gold and antimony recovery from stibnite. Hydrometallurgy Liu W., Fu X., Rao S., Yang T., Zhang D., Chen L. (2017) Selection on the Process for Removing and Recovering Antimony from Antimonial Refractory Gold Ores. In: Ikhmayies S. et al. (eds) Characterization of Minerals, Metals, and

Recovery of gold from refractory ores requires a pretreatment to liberate the gold particles from the host mineral. In particular, in the case of stibnite (Sb 2 S 3), the antimony (Sb) forms stable compounds with sodium cyanide (NaCN) during the cyanidation process; as a consequence, cyanide consumption is usually an oxidation step.

Gold processing flow sheet Gold Ore Crusher. Process flowsheet for gold and antimony recovery from Recovery of gold from refractory ores gold processing flow chart gold

Antimony production flow sheet mnquerecruitmentnl. Process flowsheet for gold and antimony recovery from stibnite, a complete process flowsheet with low, This fact determines the production of Na 2 S that can Process Flowsheet for Gold and Antimony Recovery From, production of metallic antimony from stibnite, reactor to the selected temperature under a slow flow of

leach and recover all liberated gold from the finest to the coarsest particle sizes, this process resulted in a quantum improvement in gold recovery from less than 50%, which was typical prior to the cyanidation era, to greater than 90% and often as high as 9599%, with cyanidation. The cyanidation process accounted for 8090% of all gold

WhatsApp)

WhatsApp)