cement manufacturing

Crushing can be defined as comminution (size reduction) process to reduce the size of Run of mine (ROM) Limestone/sandstone to size (1030mm) suitable

WhatsApp)

WhatsApp)

Crushing can be defined as comminution (size reduction) process to reduce the size of Run of mine (ROM) Limestone/sandstone to size (1030mm) suitable

Limestone grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. The applications of ball mills are ubiquitous in mineral processing and mining industry, metallurgy, cement production, chemical industry, pharmaceutics and cosmetics, ceramics, different

removal efficiency, the capacity of the limestone slurry preparation system was fundamental process used by ball mills in FGD systems to produce limestone slurry. For the began by examining the physical conditions of the ball mills.

You are working in a company produces limestone and handling a stone size reduction process using ball mill to break stone at average 6 mm to smaller size. During the process, many fine particles are produced due to attrition effect. These fine particles are to be removed to reduce dust hazard and ensure quality of product.

Used Ball Mills For Limestone. Limestone wet dry kaolin ball mill for ball mill is the key equipment for recrushing the materials after they are primarily crushed ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement silicate product new building material refractory fertilizer black and nonferrous

ball mill preparation limestone Limestone Slurry Preparation System Limestonebased WFGD usually requires a fairly complex reagent slurry preparation system, consisting of a limestone storage silo, weigh feeder, wet ball mill with all required accessory equipment, cyclone classifier, ball.

Ball Mills. Ball mills have been used for the preparation of coaloil and conventional coalwater slurry fuels, also in large sizes up to a capacity of 50 tonnes of coal per hour (Austin et al., 1984). From: Advances in Clean Hydrocarbon Fuel Processing, 2011.

CEMTEC India Private Limited Ball Mill, Rod Mill amp; Classifier OEM Manufacturer from Kolkata, West Bengal, India

Limestone Ball Mill. 25 rows#183; Limestone Ball mill can devide into 2 types, wet ball mill and dry ball mill. Ball mill is a . MODEL ROTATE SPEED (R/MIN) GRINDING MEDIA WEIGHT (T) SIZE(MM) 3200#215;#215;#215;#215;See all 25 rows on

Limestone Ball mill can devide into 2 types, wet ball mill and dry ball mill. Ball mill is a mineral processing machine for milling the materials into powders after they are crushed. It is widely applied to the production of cements, silicate products, building materials, fireproof materials, fertilizers, glass, ceramics as well as nonferrous and ferrous metal processing industries.

Ball Mill Design For Limestone. Our ball mills are perfectly suited for the preparation of hard and very abrasive materials operating all over the world In fact we design build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials Information on limestone preparation References feed material dedusting feed

Ball Mill (60045m) Ball mill has been used in many industries for a long time, the technology is quite mature already. But there are still some problems, such as, lots of investors expressed that the metal balls are easy to be worn out and the energy consumption is quite high.

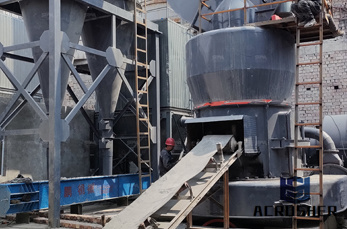

Limestone Mill High Efficiency, Large Capacity,

3x ball mill NBc360x850 wet process discharge type: over flow limestone. mean size F80: 7000 #181;. Processing plant. Germany 1x ball mill SKM1000x800. Contact US Ball Mill RETSCH powerful grinding and homogenization. A ball mill can grind and homogenize small sample volumes down to

May 07, 2015#0183;#32;Ball Mill Operation (for limestone) NHT Tv. Loading... Unsubscribe from NHT Tv? Ball mill animation demo grinding machine how does a ball mill work Duration: 2:00.

WhatsApp)

WhatsApp)