(PDF) METHODS OF SIZE REDUCTION AND FACTORS AFFECTING SIZE

Impact Mill (Hammer Mi ll) hammer mills as well as eliminates the use of burr mill by farmers in the study area as alternative to produce fine grind. ball mill was combined with pearl

WhatsApp)

WhatsApp)

Impact Mill (Hammer Mi ll) hammer mills as well as eliminates the use of burr mill by farmers in the study area as alternative to produce fine grind. ball mill was combined with pearl

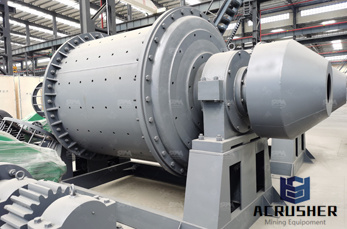

Aug 17, 2018#0183;#32;Ball Mills these use balls for grinding media breaking the coarse feed materials by impact and attrition into extremely fine powder. Ball mills use

Oct 01, 2017#0183;#32;Since high energy consumption is the main drawback of using ball mill pretreatment in industrial applications, this study focused on developing a low energy consumption process for ball mill pretreatment. 2. Materials and methods Materials. Corn stover provided by CJ Cheil Jedang, Republic Korea, was used as biomass material in this study.

New Condition And Iron Ore Ball Mill Appliion Ore Impact. May 21, 2018 model rc46 rock crusher with roller scraper mill, amazing 3 stage compact rock crusherave obtained the gold from the ore and now have no need for itess than 15 minutes of use on it, in like new condition, still on pallet from ore.

ball mill specific area cm2 kg; ball mill specific area cm2 kg IMPOTANT PARAMETERS KILN SPECIFIC VOLUME LOADING = TPD/ m3 or Specific Kiln capacity ~ t WEFT = 1200 Kg/cm2 : WARP Product Ball Mill 1 A leaf of area 44 cm2 and mass 45 104 kg . A leaf of area 44 cm2 and mass 45 104 kg directly faces.

Ball Mills. IQS Directory is a top industrial directory listing of leading industrial ball mill manufacturers and suppliers in Pennsylvania. Access our comprehensive index to review and source ball mill manufacturers with preview ads and detailed product descriptions.

Highquality ball mills are potentially expensive and can grind mixture particles to as small as 5 nm, enormously increasing surface area and reaction rates. The grinding works on

Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of #188; to The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attrition.

The Ball mill drive sets the milling drum into slow rotation and the bed of milling media is thus activated, the balls are lifted and then impact back against the bed. Ball mills are usually operated at 75% of the critical speed. The critical speed is the speed where, mathematically calculated, the grinding media would centrifuge out.

If a ball mill uses little or no water during grinding, it is a dry mill. If a ball mill uses water during grinding, it is a wet mill. A typical ball mill will have a drum length that is 1 or times the drum diameter. Ball mills with a drum length to diameter ratio greater than are referred to as tube mills.

There are many different designs and styles of ball mill liners. As with grinding balls local economics and ultimately operating costs determine the best design and material to use. The initial set of liners is rarely the final design selected. Based upon individual experience, mill superintendents develop preferences for liner designs. The following is given as a guideline for the initial set

The present invention is directed toward a material handling, processing and milling facility which utilizes ball milling as a means for material grinding, mixing or mechanical alloying of materials. The system includes an automatic ball charging, agitating and indexing assembly, constructed and arranged to deagglomerate and directly distribute a plurality of grinding balls to the facility.

Example Ball Mill GrindingExpert Solution The throughput and efciency of a SAG mill depends on the volumetric load: An overloaded mill has reduced coarse ore breakage, as the cascading balls and rock cannot drop far enough, reducing kinetic energy for breakage. An underloaded mill will break coarse ore well, but at the expense of added

Table of ContentsImpact Test BallInstrumented Ball TestsFactors Affecting Impact in Grinding Balls Of many physical parameters critical to design of grinding processes, impact of grinding media is among the most difficult to measure or predict. Yet impact of falling grinding balls, pebbles, or rods accomplishes the fine grinding essential to metallurgical recovery of most important minerals

The present invention is directed toward a material handling, processing and milling facility which utilizes ball milling as a means for material grinding, mixing or mechanical alloying of materials. The system includes an automatic ball charging, agitating and indexing assembly, constructed and arranged to deagglomerate and directly distribute a plurality of grinding balls to the facility.

An additional interesting application is the solventfree synthesis of materials in Planetary Ball Mills. Are you interested in the diverse branches of mechanochemistry? Read numerous articles on the specific subjects of mechanochemistry please keep in mind that in some cases the information may only be available in German.

Ball Mill offered by us is used for grinding various products into fine particular sizes. This can be utilized for both wet grinding as well as dry grinding applications across the industry. Our range includes cylindrical steel shell Batch Type Ball Grinding Mill with flanged steel heads, rotating on a

impact appliion in bentonite ball mill with high efficiency in zambia. small bentonite mining equipment in Kitwe Zambia Africa The best 10 Mining Equipment Manufacturers Suppliers in E C Mining Ltd Address Plot 5293 5294 Tanganyika Rd off Mutentemuko Rd Heavy Ind Area Kitwe Zambia Zambia See full address and map Categories Mining Equipment Manufacturers Suppliers Get A Quote Kitwe Zambia

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 50 % of the mill volume and its size depends on the feed and mill size.

Technical Performance and Application of Ball Mill and Rod Mill author:dua1 time: . due to the grid plate, the ball can be loaded more in the mill, and it is also convenient to load the ball, thereby increasing the grinding area of the grinding process and the number of impact crushing per unit time, so that the grinding machine

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only minor warming

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

WhatsApp)

WhatsApp)