VPA filters

VPA vertical plate pressure filters operate in the pressure range of 610 bar and are based on the air through blow dewatering concept, where water is displaced by air as it passes through a filter

WhatsApp)

WhatsApp)

VPA vertical plate pressure filters operate in the pressure range of 610 bar and are based on the air through blow dewatering concept, where water is displaced by air as it passes through a filter

Founded in 1933, Ascension Industries manufactures a broad line of selfcleaning Tubular Backwashing Filters, Pressure Leaf Filters, Pressure Nutsches, Filter Presses, and Sludge Dryers. Our worldwide customer list includes companies such as Barrick Gold, BHP Billiton, Buenaventura, FMI, Kennecott, Newmont, Rio Tinto, Vale, and many others.

Pressure Leaf Filters. Durco Filters Pressure Leaf Filters are designed for high flow rates and batch operations in applications with lt;2% solids Leaf Filters are pressure vessels containing permanent filter leaves. These leaves can be the final filtration media but typically use Diatomaceous Earth (DE) as a precoat and/or body feed to improve filtration rate and product clarity.

#0183;#32;The vertical MV Filter is an extremely economical filter which has a cover closure with eye bolts and stirrup nuts fitted as standard. A hydraulic davit is mounted for quick and easy cover opening. Depending on the application and on whether dry or wet cake is being removed, the filters are equipped with either a vibrator system or an oscillating sluice header.

At Clear Edge, we deliver pressure leaf filters for both vertical or horizontal and develop filter media precisely for your application requirements and end product. Whether your industry is food and beverages, chemicals, healthcare or transportation we deliver high performance filtration products that exceed industry standards.

Take a short trip with me to Dawson City, Canada. Have a look at how the quot;average, not for TVquot; miner gets gold. No staged arguments, breakdowns, or deadlines...

The vertical pressure filter chamber design also minimizes potential chemical exposure outside of the tower filter press, ensuring operator and equipment safety. In short, when high cake solids and higher wash efficiency are required, along with reliability and maintainability, you''ll find the VertiPress automatic filter press technology a wise investment.

The pressure leaf filter consists of a vertical or horizontal pressure vessel with a number of vertically mounted filter leaves. The leaves filter on both sides enabling a large filtration area in a relatively small vessel and plant footprint. The standard working pressure of a leaf filter is Barg and cake can be discharged wet or dry.

National Filter Media provides a full range of products for pressure leaf filters including new filter leafs, rebuilt and recovered filter leafs, synthetic and metal mesh leaf covers, gaskets, and replacement parts. Pressure leaf filters are ideal for processes that demand

Sharplex manufactures wide range of Filter Elements for vertical or horizontal pressure leaf filters for any sizes and any makes. Filters elements are manufactured with ''5'' layer or ''3'' layer design, riveted or bolted depending on the requirements. With many years of experience in manufacturing the filter

Camfil ''s Farr Gold Series#174; Dust Collectors offer an effective, efficient, and reliable solution for dust control in mining operations. They protect workers, the

Vertical Pressure Leaf Filter. Installation of 142 m2 VPLFS in one of the Refinery. 142 m2 VPLF. Installation of 3 X 50 Sq. M Sharplex VPLF at Edible Oil Refinery. For filtration of liquids with suspended solid contents upto 7%. No filter cloth requirement.

We are considered as prominent names of Vertical Pressure Leaf Filter in this industry. To meet the quality standards and norms of this industry, we engineer these leaf filters by using superior quality raw materials and stateofart technologies under the supervision of our experienced and skilled manpower.

The Vertical types of the Pressure Leaf Filter consists of the vertical pressure vessel with the filter elements mounted horizontally on general outlet manifold through which the filtrate flows out. The MOC can be IS 2062, SA 516 Gr. 60/70, SS 304, 316, 316L or as required.. The Horizontal kind of the Leaf Filter consists of the Horizontal Cylindrical vessel with the particular bayonet wedged

Diastar is a fullyautomatic pressure static vertical leaf filter. It is used for thickening or clarification of suspensions, but it can also wash and drain filter cakes. Its unique operating principle enables it to achieve particularly high specific throughputs, filtrate quality and thickening ratios. Diastar Filter : First commercialized in 1986

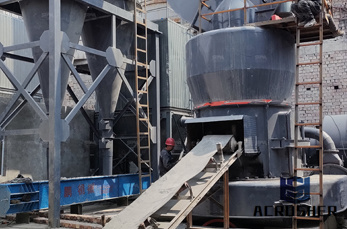

will deliver three Vertical Plate Pressure Filters gold to Salares Norte gold mine in Chile. Mining Equipment senior manager Patricio Mujica Dominguez said: The location of the plant at a height of almost 5km above the sea level comes with its own unique challenges.

The MC Press#174; filter press provides high cake discharge consistency, low cake moisture content and superior reliability coupled with greatly reduced maintenance requirements. The MC Press#174; filter press is utilized in the mining industry to process tailings and mineral concentrates in every environment, including the most rugged environments at the highest, driest altitudes.

Rotofilt Automatic Vertical Pressure Filter ensures the driest cake and high yield of the product with marked reduction of energy consumption. Rotofilt Automatic Pressure Filter is a state of art equipment with proven technology and matches the features with the worldclass manufacturers.

Pressure Leaf Filters are pressure vessels with vertical mounted leafs accumulated on central outlet filter manifold. These filters are equipped with pneumatic vibrator and pneumatic controlled valve at bottom for quick release of cake dry or wet.

WhatsApp)

WhatsApp)