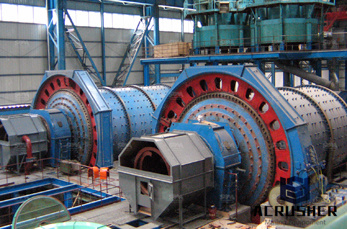

Ball Mills Iron Ore Equipment

ball mills iron ore equipment SBM Ball Mill. SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the ball mills iron ore equipment, sand amp;

WhatsApp)

WhatsApp)

ball mills iron ore equipment SBM Ball Mill. SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the ball mills iron ore equipment, sand amp;

Rod amp; Ball Mills. The Ball/Rod mills are meant for producing fine particle size reduction through attrition and compressive forces at the grain size level. They are the most effective laboratory mills for batchwise, rapid grinding of mediumhard to very hard samples down to finest particle sizes.

Secondary Grinding Ball Mills In secondary ball milling, abrasive and corrosive conditions predominate. The smaller balls [lt; 2#189;, (65 mm)] typically used in secondary milling environments effectively reduce the impact component of wear to the point where grinding media must be primarily designed to reduce abrasive and corrosive wear.

ore milling equipment if can can break through the critical speed, production capacity of mill improves, and still with the mill in above the critical speed increase with the increase of the rotational speed, so it can achieve the goal of mill miniaturization, production capacity of largescale, for mineral processing, chemical and building materials such as grinding development of traditional

#0183;#32;Working Continuously 5. Quality guarantee, safe operation, energysaving. The ball grinding mill machine usually coordinates with other rock crusher machines, like jaw crusher, cone crusher, to reduce the ore particle into fine and superfine size. Ball mills

Ball Mill Ball mill is ore dressing equipment, mainly used for crushing bulk ore materials into ore pulp, for further separating operations.; Spiral Classifier Spiral separator is large grading equipment. This machine classifies materials according to the different sizes and proportions of solid particles. Magnetic Separator Magnetic separator is common used magnetic separator machine

Industrial Ball Mills use horizontal rotating cylinders that contain the grinding media and the particles to be broken. The mass moves up the wall of the cylinder as it rotates and falls back into the toe of the mill when the force of gravity exceeds friction and centrifugal forces.

#0183;#32;Crushing Equipment and Ball Mill In Gold Ore Processing machinery The top products will be crushed again and then mixed with the middle products for together secondary crushing.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc., as well as for ore dressing of ferrous and nonferrous metals. The ball mill can grind ores and other materials, wet or dry.

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Ball Mill: Iron Ore Processing Equipment, Star Trace offers turnkey solutions for Iron ore processing plants. We are one of the leading project suppliers for coal plants and we work closely with our customers to fulfill their specific needs.

Ball mill is one kind of ore beneficiation equipment, which is mainly used in ore processing operation and commonly seen in ore processing plant. It can grind small pierces of ore into very fine particles, thus preparing for subsequent processing. After being ground by ball mill, ore

Below is the writeup of how a ball mill works, is used to crush ore and an explanation regarding its effectiveness in gold mining. The Purpose of Milling First of all, in order to get the best out of how this particular equipment is used it is important to get acquainted with knowledge on what it

Crushing and grinding equipment Stone crusher, ore grinding mill, mobile crushing production line Whether you purchase this equipment for your home or your business, you can be assured that you are getting something that has been manufactured to the highest degree of quality possible, by a team of people who are committed to excellence.

Ball Mills Capacity From T/H AdvantagesDesigned for long service life, minimum maintenance, can grind and homogenize mineral ores down to the nano range, large volume of processing capacity Max Feeding size lt;25mm Discharge Typesoverflow ball mills, grate discharge ball mills Service 24hrs quotation, custom made parts, processing

Ball mill is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control. II. Application: Ball mill is the key equipment for smash the materials after they are primarily crushed.

WhatsApp)

WhatsApp)